With the advancement in the printing world, over the last few years, the graphic printing and the textile printing industries have adopted digital printing methods due to the amazing opportunities of personalised printing, cost-efficiency, and flexibility of the machines connected with it.

Know More

500 to 1830cm

200 to 4000 meter

50-90 gsm

180-220

95%-98%

20-30s

2 - 3 minutes

Bright color, washable, natural color

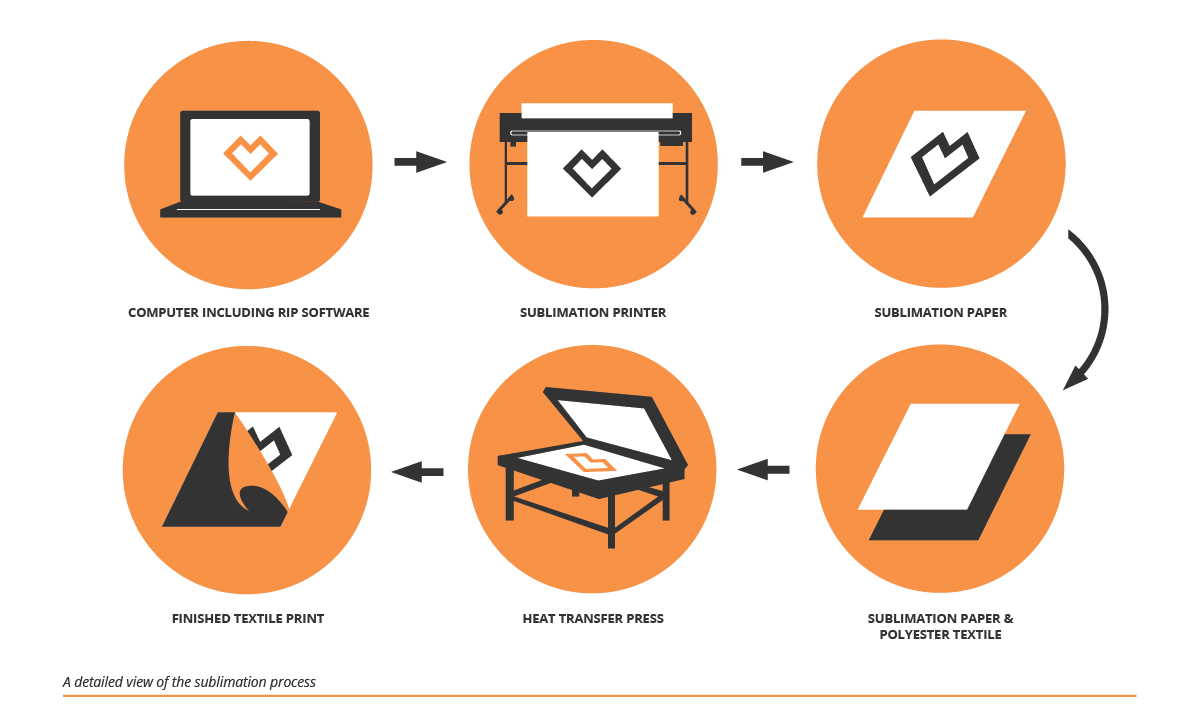

First, a design is printed on special paper. The inks that are used turn into gas when brought under heat, then combine with the fabric and permanently print on the fabric. The effects are permanent and less prone to fading, as the ink is embedded in the fabric or substrate rather than simply laying on top like a normal print.

The process is almost like a tattoo, but instead of for your skin, it’s for your chosen product. The heat opens up the pores of the fabric, then with the applied pressure the ink cools and returns to a solid form.

The result is a permanent, full colour image that won’t crack, peel or wash away from the substrate. The process allows the ink to go from a solid to a gas without turning to liquid, a bit like dry ice. The conversion is initiated by heat and controlled by pressure.

Apparels

Sarees, suits, dupatta, lace borders, Lycra materials, cycling, Polyamide, Swim & Surf wear, 100% polyester (stretch), running, ice hockey wear, Sports and functional textiles.

Home Usages

Curtains, Blinds, Cushions, Table Covers, Towel Cleaners, etc.

Advertisement

Flags, Banners, Felts, Gaming tables, Home Textiles.

& many more...